How I turn Stone into Bronze...

The first time I got to cast sculpture was at Denison University. We created odd shaped impressions in green sand into which we poured hot aluminum. I was hooked. My first bronze casting was only 5 inches high because we had a limited supply of bronze. I transferred to Rhode Island School of Design in my junior year so I could complete a BFA. The lure of RISD was a professor and artist, Tom Morin, who was experimenting with aluminum casting and Styrofoam molds. While at RISD I eventually ran the Foundry and developed a reputation for mold making and bronze finish work. I also discovered my love for stone carving at RISD. I graduated in 1980 and went to work for a sculptor ‘Royce’ in California. He hired me to mold and cast his bronze work in exchange for a block of stone and a carving bench in his studio.

Creating a mold of EFFLEURAGE

The piece I carved out of that block was ‘Nautilus’. I was intrigued with the idea of casting my stone sculptures in bronze. I knew that Rodin had his original stone sculptures cast into bronze. I think it gives the bronze piece more integrity if it comes from original existing work rather than a clay or wax model. So I covered Nautilus in silicon rubber and fiberglass. I was so nervous I would break the piece because of its delicate shape, but when I pried the mold apart, I had done it. The piece was cast in 6 pieces and I did the finish work & the patina.

Stone NAUTILUS - Carrara Arrebescato Marble

Bronze NAUTILUS with Black Granite Patina

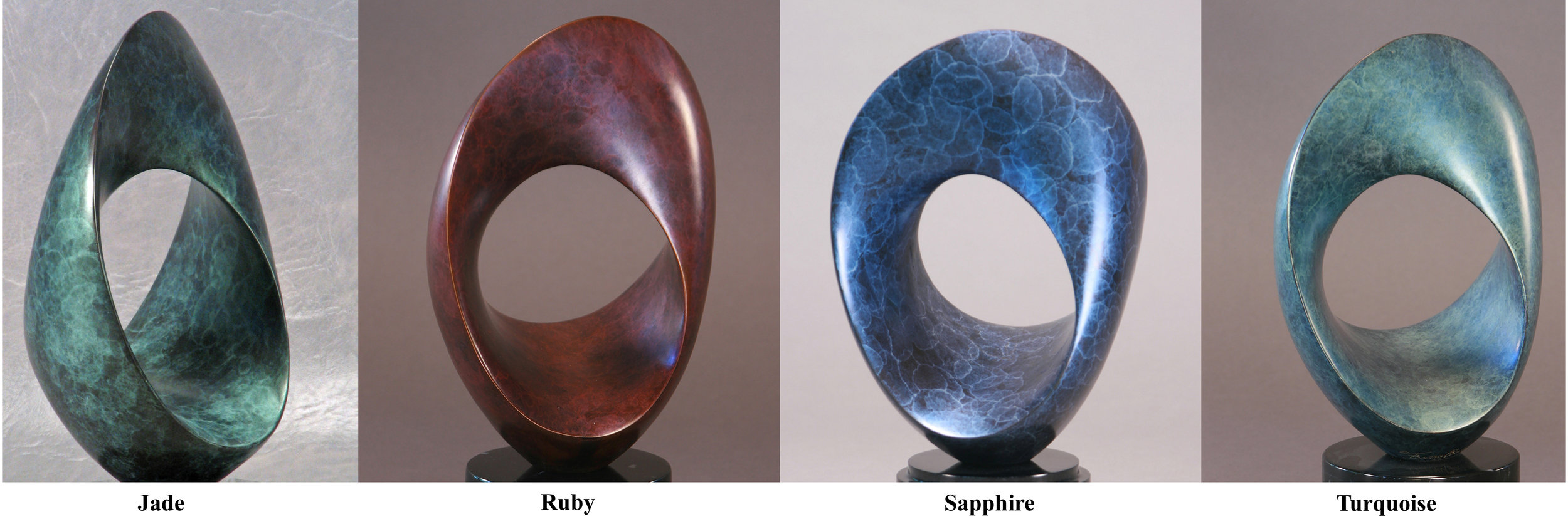

Over the years, I have created bronze sculptures from 10 stone pieces. I use 4 patinas created for my work: jade, ruby, sapphire and turquoise.

The four Patinas

Today, I don’t have to endure the agony of watching my sculptures being covered in fiber glass. Now they are scanned and a copy is printed in poly vinyl acetate. The really exciting aspect of this scanning process is that I can make the piece as large or as small as I want. Thus I have now created jewelry and an 8 foot tall replica of my stone sculpture “Circo”.

the 4 "trefoils’ - the smallest is a Wearable CIRCO, then CATENA X, CIRCO and the largest is CIRCO X